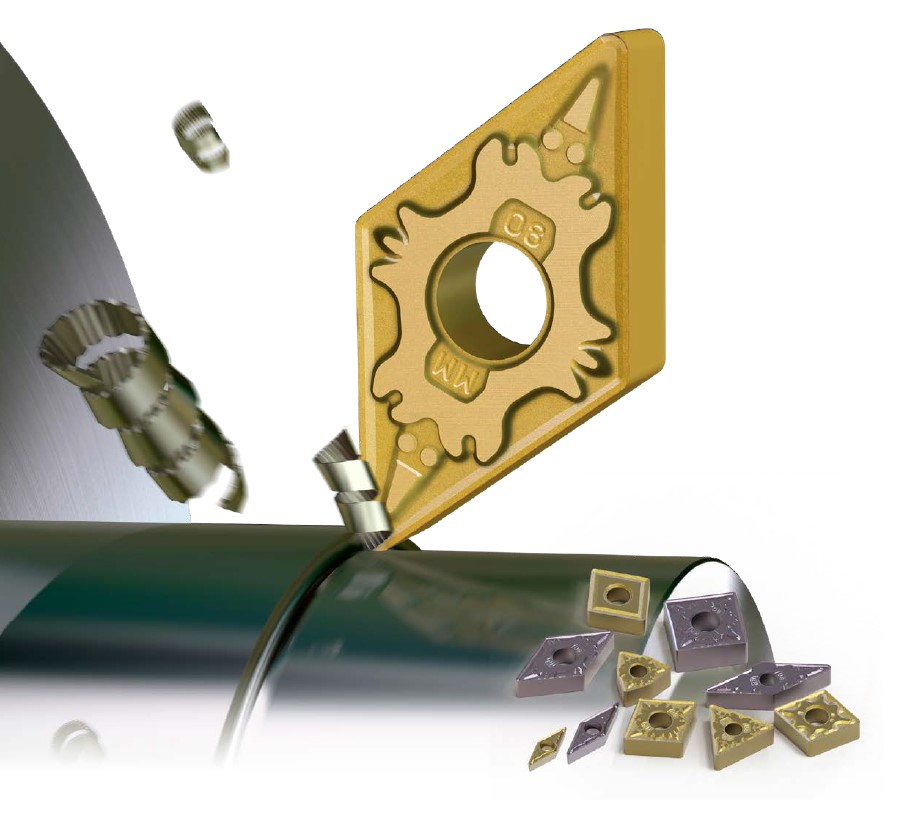

Effective chip removal WWX SERIES

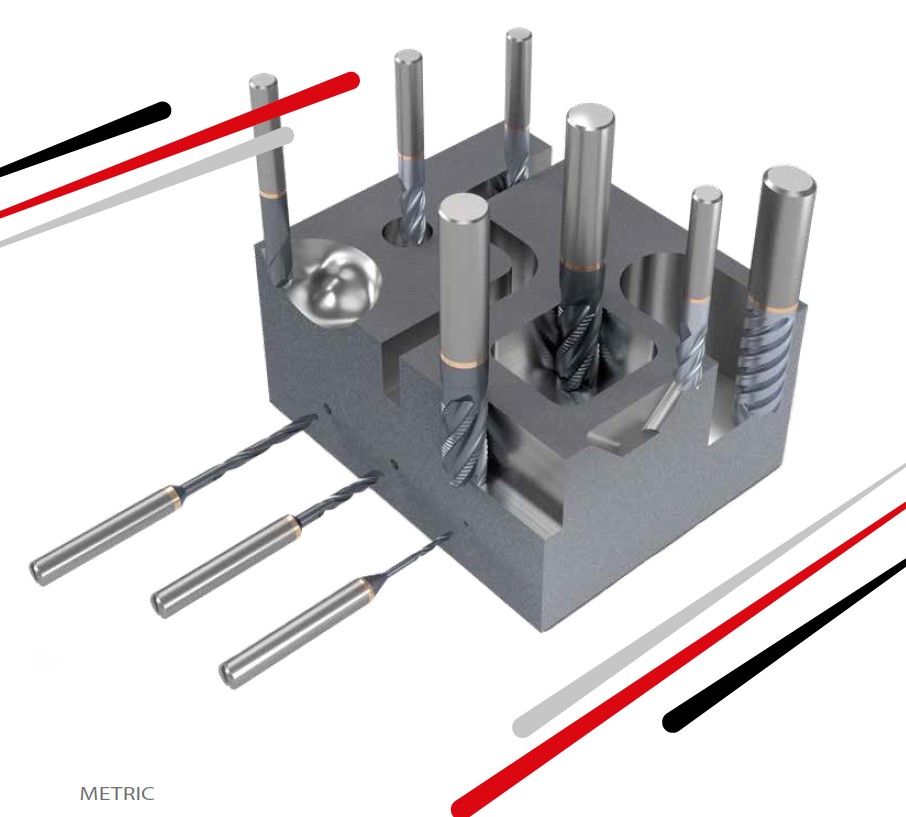

High-performance end mill for 90˚ end milling with double-sided triangular inserts, suitable for end milling, shoulder milling, and copy milling.

Indexable inserts with 6 usable cutting edges provide a lower edge cost and excellent process reliability thanks to a special negative geometry combined with positive, sharp cutting.

The precise positioning of the plates ensures accurate 90° milling, eliminating the need for additional operations and saving valuable time and production costs.

FEATURES:

• Low cutting force

• Effective chip removal

• Wide selection of plates and geometries for various applications

• Double-sided triangular plates with 6 cutting edges

• Excellent surface finish quality

Selection and availability

Diameters from 25 to 160 mm (WWX200) and from 50 to 250 mm (WWX400) are available with coarse, fine, and extra-fine pitch geometries.

The wide range of sizes allows for optimal selection of the milling cutter body for a variety of applications.

In addition, each milling body has internal cooling directed directly at each plate.

PERFECT PROCESSING OF WALLS AT AN ANGLE OF 90° AND PLATES WITH A MAXIMUM CUTTING DEPTH OF UP TO 5 MM (WWX200) / 8 MM (WWX400)

The intelligent positioning of the blade ensures extremely low cutting resistance and enables precise machining of walls at a 90° angle under all cutting conditions.

LOW CUTTING POWER

The innovative geometry of the insert creates low cutting forces.

The increased thickness of the plate provides excellent resistance to breakage.

Large radius of the auxiliary cutting edge

In order to meet modern requirements for high-quality surface treatment, all L, M, and R type chipbreakers use a specially defined radius (R = 100 mm) and a cutting width BS of 0.5 to 1.7 mm, which acts as a wiper geometry.

PLASTIC SHEETS

Precise positioning of the plates in combination with secure fastening

Four contact surfaces in the plate socket, together with the use of a large clamping screw, ensure precise, stable, and secure fixing of the plates.

Thanks to this, the WWX200 and WWX400 series are an excellent choice for both roughing and finishing.

Shoulder and wall machining without worrying about chips

The protruding main cutting edge ensures clean 90° shoulder milling and prevents contact between the chip and the workpiece.

CLASSES AND CHIP-BREAKING GEOMETRIES

The wide range of grades and chipbreaker geometries ensures the optimal choice for stable and efficient machining in various applications and materials.

L-GEOMETRY

Recommended for applications requiring low cutting forces, as well as for machining heat-resistant superalloys (HRSA materials).

M-GEOMETRY

Excellent balance between cutting edge sharpness and stability. A basic universal choice – suitable for different materials and working modes.

R-GEOMETRY

Recommended for interrupted cutting – ensures high reliability and durability of the cutting edge.

Classes for processing a wide range of materials

MV1020

This grade offers excellent wear resistance and thermal shock resistance, ensuring stable operation even at unprecedented cutting speeds.

Particularly effective in machining steel and malleable cast iron, significantly reducing machining time.

MV1030

The new coating with high aluminum content provides exceptional wear resistance.

The grade demonstrates high resistance to sudden breakage, especially under difficult wet machining conditions and when working with stainless steel.

MP6120

For general milling of steel.

MP6130

For interrupted milling of steel.

MP7130

For general milling of stainless steel.

MC5020

For general milling of cast iron.

MP9120

For general milling of HRSA materials and titanium alloys.

MP9130

For interrupted and continuous milling of heat-resistant superalloys (HRSA) and titanium alloys.

TF15

For general milling of aluminum.

VP15TF

Provides stable processing thanks to the combination of a highly wear-resistant coating and an impact-resistant carbide substrate.

CONTACT

+359 66 80 03 49office@timextools.com